Smart Home Solutions for Mold Prevention

Mold. The four-letter word no homeowner wants to hear. It lurks in damp corners, ruins drywall, and makes your house smell like a wet basement

Mold. The four-letter word no homeowner wants to hear. It lurks in damp corners, ruins drywall, and makes your house smell like a wet basement

When people think of mold, they usually picture those blotchy, fuzzy stains creeping along the bathroom ceiling or hiding behind a forgotten cardboard box in

If you’ve ever cracked open a wall to find a science project’s worth of mold colonies hunkered down, you know how nasty this stuff can

Mold in your crawl space can damage your home and impact your health. Learn the risks, signs, and best prevention and removal methods to protect your home.

“Discover how fitness centers can prevent mold growth with humidity control, ventilation, and cleaning tips to keep gyms safe, clean, and mold-free.”

Mold in warehouses threatens inventory, operations, and health. Learn how to detect, prevent, and remove mold to protect your business and assets.

DIY Mold Testing vs. Professional Mold Inspection: Learn the pros & cons of each method to detect mold, protect your home, and decide which option is best for you.

Learn how to detect, remove, and prevent Mold in Your Vacation Rental to keep guests safe and protect your property from damage and negative reviews.

Long-term exposure to mold can lead to respiratory issues, immune complications, and more. Learn symptoms, risks, and prevention tips to protect your health.”

Discover the risks of mold in hotels, its impact on guests, and best practices for prevention and remediation to protect your business and reputation.

Can Mold Shut Down Business? Yes! Learn how mold can threaten operations, cause health risks, and lead to closures—plus tips to prevent and address mold issues.

Learn about the mold remediation process step-by-step, from inspection to cleanup and prevention. Ensure a safe, mold-free home with expert tips.

Discover the top signs you need professional mold removal services right away. Protect your home & health—act fast to prevent damage and mold exposure!

Learn what’s covered under mold insurance claims, what’s excluded, and how to maximize your claim to avoid costly out-of-pocket expenses.

“Learn how to spot mold in commercial kitchens fast. Identify signs, tackle problem areas, and protect your business from health risks and costly shutdowns.”

Discover hidden mold in your home with these essential tips. Learn to spot, detect, and prevent mold to protect your health, property, and peace of mind.

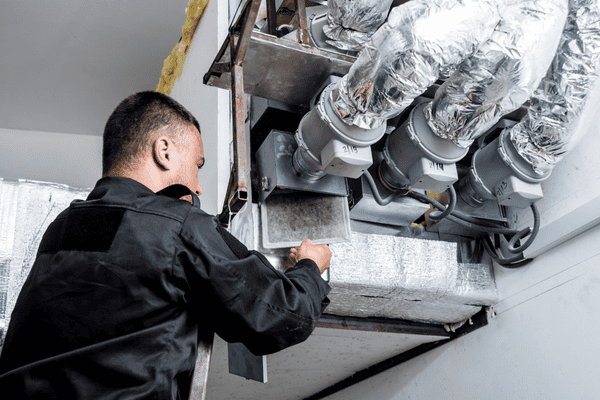

When Your HVAC Turns Into a Mold Factory: What You Need to Know Imagine turning on your air conditioner, expecting a cool breeze, and instead

The Unwelcome Guest: Why Bathroom Mold Refuses to Leave Bathroom mold has a knack for overstaying its welcome. You scrub, you clean, and just when

Ah, Christmas—the time for twinkling lights, festive music, and unpacking that box of decorations you’ve had tucked away in the attic. But what’s that smell?

If you’re running a business in Austin—or anywhere in Central Texas, really—you’ve probably had to deal with your fair share of challenges. But here’s one

When it comes to homeownership in Austin, you’ve probably tackled your fair share of challenges—maybe a leaky roof, a stubborn AC unit, or the occasional

At All Nation Restoration, we pride ourselves on offering comprehensive restoration services to homeowners and businesses in Austin and beyond. Whether you’re facing water damage,

You’re planning a cozy attic retreat, or maybe you’re just storing seasonal items up there. But when you open the hatch, a musty smell hits

Greetings, modern-day homeowners! Here in Austin, Texas, where many of us are relentlessly pursuing energy efficiency, our homes have transformed into snug airtight cocoons, experiencing

Mold is a common problem that can seriously affect our health and our homes’ structural integrity. It thrives in damp and humid environments, making basements,

Leasing a property can be exciting, but it’s essential to be aware of potential issues that may arise during your tenancy. One such issue is

The Sneaky Culprit Behind Fall Colds and Flu: Could It Be Mold in Your Central Texan Home? Fall in Austin, Texas brings relief from scorching

Typical Questions Regarding Mold Removal Mold growth is a common problem in many households and businesses, especially in humid and subtropical regions like Round Rock

People from all over move to Austin, Tx for its beautiful weather. The sunshine and warm air feel amazing for just about anybody; mold shares

1. Leaking appliances Leaking kitchen appliances, such as dishwashers, refrigerators, or icemakers, are common culprits that lead to mold growth in apartments. These appliances often

Mold growth in your home is more than an unpleasant sight, it’s a health hazard to your family, especially to those who are sensitive to

Mold thrives in moist environments and has been around for millions of years. Left to grow, mold spores that get into the air are a

Case Study Information We received a call from the homeowner in a panic as she had just seen the damage to her rental property. The

Fairly insignificant water damage caused very significant mold damage to a book vault at the University of Texas. The Damages: An HVAC leak caused

All Nation Restoration specializes in restoring homes and rebuilding lives. Our highly trained technicians are dedicated to providing fast, reliable, and friendly service to our clients.